About Us

Shree Matangi Woven Sack Pvt. Ltd. (SMWSPL) is promoted by 2nd generation entrepreneurs of Matangi Group. With over Rs.300 Crores in annual turnover, Matangi group of companies have over 50 years of experience across Logistics, Paper, Chemicals and Plastic industry. The Young & Experienced management team brings together new product innovation & technology with best business practices.

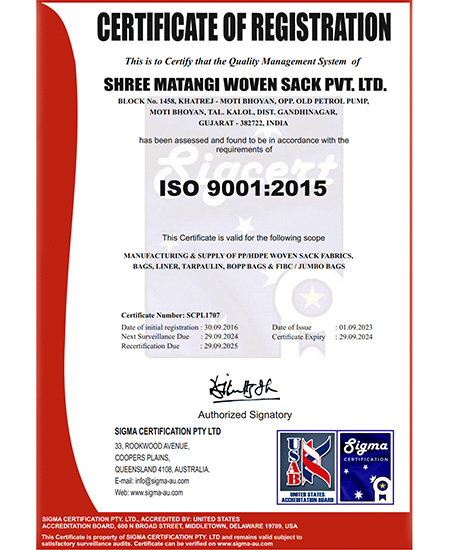

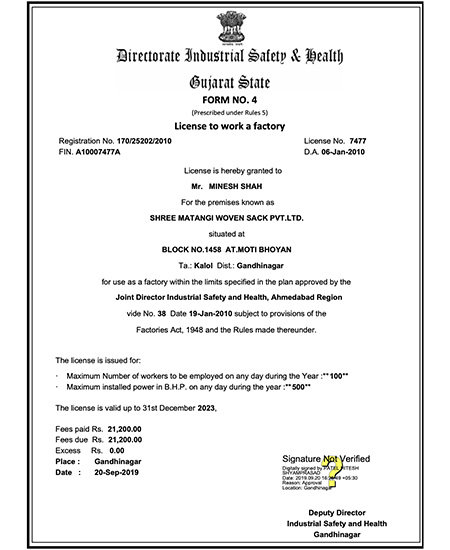

SMWSPL is one of the leading manufacturers of HDPE/PP woven sacks and fabrics. Our manufacturing plant is located in the heart of plastic woven sack industry in India at Kalol, Gandhinagar, Gujarat,. SMWSPL is equipped with state of art machinery and has in house testing facility from tape to load testing.

Our product range includes

Jumbo Bags, BOPP Laminated Bags, PP/HDPE woven sack,PP/HDPE low GSM wrapping Fabric, PP/HDPE laminated bags.

We serve Cement, Fertilizer, Sugar, Chemical Powder, Food Grains, Spices, Soya beans, Minerals and other industries for their packaging needs.

Mission Vision

Integrity, hard work and business discipline are the 3 strong pillars of Matangi Group of companies. Our customer Centric approach is the reason of our 50 years of success. Investing in human resources and technologically advanced machines has always differentiated our offering and help us stay ahead of competition.

Our quality and eco-friendly offerings at competitive pricing makes us preferred vendor to most companies. Matangi group strongly believes in greener planet. Our association as the green sponsor provides us the platform to communicate our philosophy of 'Eco Ideas' that champions the cause of greener environment.

(Director)

Products

Matangi Woven is manufacturer of PP/HDPE Woven Sacks and Fabrics. It has many products in offering.

- HDPE/PP Woven Sack and Fabrics

- Low Gsm Wrapping Fabrics

- Laminated and Unlaminated Bags

- Fabric sheets

Woven Sack and Fabric Details

Size

Width - 15" (380mm) - 36" (915mm) Length - As per customer specification

Printing

Upto 6 color Flexo - Printing Single / Double sided

Materials

PP / HDPE

Fabric Weave(Mesh)

5*5 to 12*12 Sq.Inch

Tape Width

Standard - 2.5 mm, other width on request

Denier

500D - 1800D

Fabric Color

Natural, Milky and Colored

Lamination

Laminated and Unlaminated

Applications

Fertilizers, Cement, Sugar, Food Grains, Salt, Minerals, Chemical and Packagin

Infrastructure

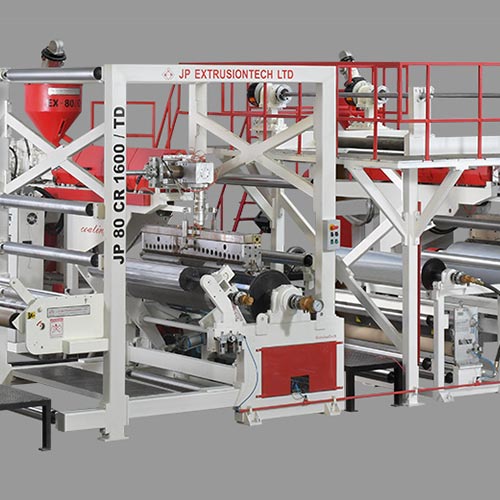

Matangi Woven is spread over 72000 sq.ft of area. It has world class infrastructure and it is constructed in eco friendly ways. We are equipped with latest Lohia starlinger tape line. Plant is equipped with mixing unit, for uniform flow we have EDI die and long hot air oven for better molecular orientation.

Centralized computer system for extrusion and chilling plant provides various data which can be stored. State of art extrusion helps in producing tapes of high strength and better elongation. Each batch is checked with respect to its denier, strength and color.

Circular weaving looms of Lohia is equipped with electronic computer system and AC drives mechanism for producing no defect fabric. It is also equipped with automatic break detection sensors.

We have in-house 6 color Printing, stitching and cutting facility.

We have strict Quality Control policy. Matangi Woven is equipped with latest machines to check quality with respect to:

Denier, Tape Width, Color Matching, Load Testing

Three way inspections are done by our professional team before dispatch to the buyer.

Machines that are installed at our unit

Woven Tape Line (Extruder)

Circular / Flat Woven Looms

Coating / Laminating Plants

Monolayer Liner Plant

Cutting Machine

Stitching Machine

Flexographic Printing

Automatic Bag Conversion

Factory Address

Bhoyan - 382 721. INDIA

Taluka - Kalol (N.G), District: Gandhinagar.

Email: info@matangiwoven.com